Metalworking

Selton LLC offers the manufacture of metal products at our facilities, as well as its processing, namely:

- metal cutting

- perforation

- rolling

- sheet edge bending,

- stamping/pressing,

- welding

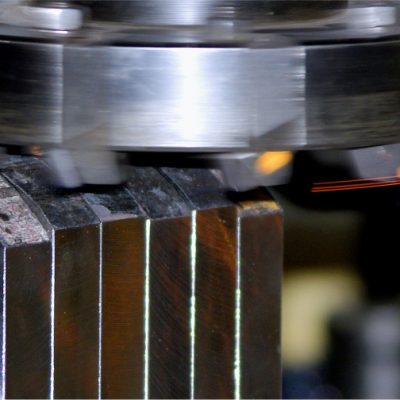

- turning, milling and grinding operations,

- sandblasting,

- painting.

We can produce products of any complexity, from simple designs to unique ones.

Our advantages:

- extensive work experience,

- convenient logistics,

- highly qualified personnel,

- modern equipment,

- quality assurance.

We use the following equipment for:

- Metal cutting

INTECUT -5, plasma cutter, δ – 5-100mm,

F1530T, laser δ <8mm, table 1500*3000mm, accuracy – 0,5mm,

HBS-1018 W band saw Ø<250mm,

RGS 3150×3, guillotine 3130*3 mm, stainless steel – 1,5 mm.

- Perforating

Trumpf TruMatic 1000. Laser punching

CNC press max. δ<6,4 mm, (AL <5,0 mm., Cu <6,0 mm.),

table 1250*2500 mm, laser 3 kW;

- Rolling

RME 70/153 rolls l = 1530 mm., δ < 1.2 mm;

4R HMS 1270*130 rollers l = 1270 mm, roll Ø 130 mm,. δ < 5 mm;

- Edge bending

Trumpf TruBend 3100, CNC press δ<2.5 mm,

length -3060 mm, force – 100 tons;

- Stamping/pressing

OMA mod.666B force – 100 tons,

KG2132 160 tons;

- Turning and milling works

1M63 (lathe) Ø above the bed – 630 mm,

Ø over the slide – Ø 350 mm, VMTs – 1500 mm.

6T10 (milling) table 1250*630*400 mm,

371M1 (grinding) table – 630*200*320 mm;

- Welding

- Sandblasting

- Painting

Turning and milling machine group manufactured by HAAS

- ST-20, Haas turning center

X-axis travel – 213 mm..,

Z-axis travel – 572 mm.

chuck Ø – 210 mm,

largest bar Ø – 64 mm,.

max. workpiece Ø – 533 mm,

accuracy – +/- 0.005 mm;

- ST-30Y, Haas turning center

X-axis travel – 239 mm,,

Y-axis travel -± 51 mm,.

Z-axis travel – 826 mm,

chuck size Ø – 254 mm,

maximum bar Ø – 76 mm,.

max. workpiece Ø – 533 mm,

accuracy – +/- 0,005 mm;

- VF-5/40XT, vertical VC. Haas

table size X,Y – 584x1575mm,

X-axis travel – 1524 meters,

Y-axis travel – 660 mm,

Z-axis movement – 635 mm,

distance between the surface of the table

and spindle face – 107-742mm,

max. weight of the workpiece – 1814 kg;

- UMS-1000, Haas five-axis machining center

table surface Ø – 635 mm,

B-axis tilt range, deg. – +120,-35,

C-axis rotation, deg. – 360,

X-axis movement – 1016 mm,

Y-axis travel – 635 mm,

Z-axis movement – 635 mm,

distance between the table surface and

spindle face – 102-737 mm…,

max. weight of the workpiece – 454 kg.

Metalworking: features and advantages

Modern metalworking with the use of high-tech equipment helps in the manufacture of parts and products with individual parameters. Taking into account the peculiarities of performance, today in Ukraine you can order prefabricated structures and individual elements, the dimensions of which are specified by the customer.

Features of metalworking

The use of professional machine tools and strict adherence to technology ensures that metal processing will be carried out taking into account the dimensions that are voiced by the customer. Thanks to the individual approach there is an opportunity in the manufacture of structural elements of non-standard shapes. Before starting work, the client provides a drawing and sketch of the finished model. If the documents are not available, designers and engineers are involved in their creation. When developing the drawing, the peculiarities of operation of the future product, regulatory documents and compliance with safety rules are taken into account. The service is paid separately.

Advantages of metal processing

Among the advantages that distinguish metal processing, we can emphasize:

- the use of modern equipment, which guarantees the exact compliance of the dimensions of the finished part or product with the declared parameters (professional machines work with a minimum error, which eliminates the need for further processing);

- efficiency (metalworking services, provided that we cooperate with professionals, are performed within strictly agreed terms, the speed of order production depends on its volume and complexity);

- individual approach (thanks to the use of high-tech equipment, it is possible to customize a product with a non-standard diameter or other parameters).

An additional advantage, which is characterized by metal processing on modern equipment, is the quality of work. Compliance with the norms of the technological process guarantees that the finished product for a long period of time will not lose its operational characteristics.

The main types

Taking into account the specifics of the equipment used, the following types of metal processing can be distinguished today

- mechanical;

- thermal;

- pressure treatment.

A little more detail. Different types of machine tools are used for metal machining in Kyiv: turning, drilling, milling, grinding and other options. Processing here is carried out by mechanical impact on the workpiece, taking into account its characteristics and the planned scope of use.

Pressure processing is characterized by affordable prices. Rolling, pressing, stamping, and other types of work affect the metal, which helps to change its physical and chemical properties. As a result, the material becomes stronger and more resistant to mechanical and temperature effects.

Popular types of metal heat treatment include hardening and annealing. Both types are aimed at improving strength characteristics, which expands the scope of the finished product.

Plus: today you can order chemical metal treatment. Its task is to increase resistance to external influences. An illustrative example is galvanizing the model, which makes it impossible for corrosion processes to develop regardless of operating conditions.

Metalworking to order

Metal processing services that can be ordered by contacting our company’s specialists:

- perforation

- edge bending according to individual parameters;

- sandblasting, which guarantees high-quality cleaning from all types of contaminants;

- painting with polymer or powder coatings.

The cost of metalworking services is negotiated separately. For more information, please contact our operators.

Check the price