Content:

- Design features and operating principle

- Advantages of FBLM filter boxes

- Specifics of the filter elements: what is the difference between the FBLM with HEPA and its counterpart with ULPA filter?

Actual equipment of modern ventilation and air purification systems is a filter box FBLM, which can clean the air mass almost at the molecular level. The manufacturer «Selton» (Ukraine), well-known on the world market, offers to buy the appropriate device.

Design features and operating principle

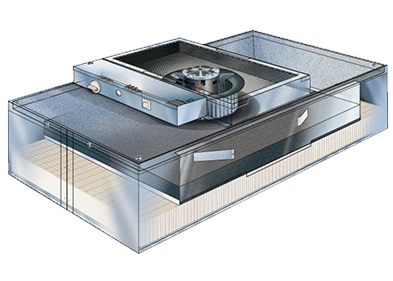

The FBLM modular filter box is a structure with a metal housing made of stainless steel, heavy-duty aluminum or galvanized steel. This fixture is equipped with an integrated fan, a special humidifying screen, and a high efficiency plate filter element. It performs air suction followed by intensive filtration. The mass of air, passing through the large filtering surfaces, at the output is completely free of harmful particles, including the smallest fractions. Depending on the modification, such devices are distinguished by the diameter of flanges from 100 to 150 mm.

Advantages of FBLM filter boxes

FBLM ventilation filter is in demand and has a wide range of applications, as it has a number of advantages:

- durability of materials, which provides a long service life of the product — the life cycle of the filter-box of the relevant specificity is up to 7 years;

- the noise level is low at 41 dBa;

- modular, universal design — it makes it possible to use air purification equipment in rooms of different shapes and sizes;

- HEPA filters with different filtration classifications can be added to the device, bringing purification to an almost sterile level;

- it is not necessary to connect ducts to this filter — it functions as an independent ventilation system.

FBLM filter operating costs can be cut in half by using prefabricated modular cleanrooms.

Key features:

|

Connection diameter |

Width, mm |

Length, mm |

Depth, mm |

Performance metal |

|

100 |

462 |

462 |

438 |

OC / NJ |

|

125 |

475 |

475 |

428 |

OC / NJ |

|

150 |

600 |

600 |

478 |

OC / NJ |

|

200 |

615 |

615 |

448 |

OC / NJ |

|

250 |

615 |

920 |

488 |

OC / NJ |

|

300 |

615 |

1225 |

428 |

OC / NJ |

Specifics of the filter elements: what is the difference between the FBLM with HEPA and its counterpart with ULPA filter?

FBLM models with HEPA are considered high-efficiency filters. The ability of these elements, which perform a comprehensive cleaning of the air mass, is impressive: they capture more than 99.9 fractions as small as 0.3 microns.

Cleaning systems based on HEPA filters are used in medical institutions, they are recommended for the equipment of rooms with people prone to allergies and small children.

For the manufacture of these filter elements, which retain viral and bacterial microflora, plant pollen and other allergens, sheets of fiberglass material folded in an «accordion-like» manner are used. A plate of synthetic fiber material is placed inside a metal casing.

ULPA filters guarantee ultra-high efficiency filtration and are capable of maintaining sterile air purity. Their filtration efficiency is up to 99.999995%.

Such equipment is used in nuclear power plants, nano-laboratories and surgical operating rooms.