Air Filters

The company «Selton» offers a wide range of filters for purification and preparation of air of various designs and classes of purification.

You can buy pocket, panel, sleeve and cylindrical air filters by contacting the contact numbers listed in the Contacts section.

Relevance of installing filters for air purification

Filter elements for air purification are used in almost all applications from domestic air purification systems to industrial air treatment for gas compressor units or pharmaceutical production.

Depending on the installation site and equipment, they can also be used to remove mechanical particles, droplets of moisture or suspended solids.

The use of air filters in industrial equipment protects system components from premature wear or contamination, thereby extending service intervals and reducing the cost of replacing equipment parts. Both the cylindrical air filter and the industrial air filter can handle these tasks with ease.

Filter classification

Air filters can be divided into the following groups according to the cleaning fineness:

- coarse cleaning;

- fine cleaning;

- ultrafine cleaning.

Coarse air filters include products designed to trap particles larger than 0.4 microns.

Fine air filters include products designed to retain particles sized 0.4 microns with an efficiency of at least 40%, but not more than 98%.

Ultrafine air filters include products that ensure cleaning from particles and aerosols sized less than 0.4 microns. See more details about ultrafine air filters and order by clicking the link.

Pocket filters

Pocket filters for ventilation are the most common type of filters for ventilation and air conditioning systems.

Pocket filters are designed to remove dust (contaminants) from outdoor and recirculating air in the supply ventilation, air conditioning, air heating systems, and in other air preparation systems.

A pocket filter for ventilation consists of a galvanized or plastic frame and filter material soldered (welded) in the shape of pockets. Optimally aligned design of the pocket filter provides for maximum performance and high dust holding capacity with low airflow resistance. Pocket filters feature longer service life and good ability to retain contaminants, various impurities.

Selton LLC manufactures pocket filters of G3 – F9 cleaning classes according to EN 779 (DSTU 4319).

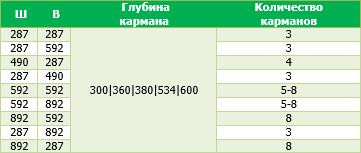

Table of standard pocket filter sizes

Panel filters

Panel air filters (frame) are no less popular than the pocket filters. They differ with more compact dimensions and can be installed in equipment or systems of limited dimensions. Compared to pocket filters, these filters have a number of advantages and disadvantages.

The advantages of panel filters are their small sizes and high performance in systems with low air flow. In case of pocket filters used in ventilation systems with low air flow, there is a possibility of pocket ‘folding’ and, as a result, a surge in resistance on the filter itself.

The disadvantages include a smaller cleaning area and, accordingly, a lower dirt holding capacity of the filter in general as compared to a pocket filter of a similar frame size.

Like filters, pocket filters, panel filters for ventilation are made with purification classes from G3 to F9 according to EN 779 (DSTU 4319).

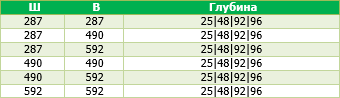

Table of standard dimensions for panel filters

Bag filters

Air filters of bag type are designed to purify air from dust in the metallurgical, food, construction industry and other industries. Bag filters are made using modern highly effective filtering materials. Reliable operation of bag filters is ensured by the use of bags made of highly efficient and durable filtering materials, as well as by the manufacturing (tailoring) quality of the bags.

In order to meet today’s high requirements that a bag filter must meet, we use filter materials that set it apart from others:

higher cleaning efficiency (filtration) – up to 99.99%;

higher cleaning efficiency (filtration) – up to 99.99%;- ability to capture fine dust;

- use of special materials for effective capture of aerosols;

- high temperature resistance;

- high wear resistance, which increases their performance;

- resistance to aggressive environments;

- moisture and oil resistance.

Industrial air filter, which can be purchased from us, is a way to make the room «clean» and human-friendly.

Related articles:

- 01. Various industries (pharmaceutical, food, mechanical engineering, metalworking, instrumentation, light industry, etc.);

- 02. In the electric power industry, gas and oil refining industries (in gas turbine engines and compressor units, etc.);

- 03. In air preparation systems for painting and drying chambers, paint and varnish production lines and other production processes, where necessary;

- 04. In buildings for various purposes (office and business centers, residential, administrative, warehouse terminals, airports, shopping and entertainment centers, industrial, etc.);

- 05. At catering establishments (restaurants, cafes, canteens, etc.).