Content:

Introduction

Why use a hepa filter? HEPA, which stands for «High Efficiency Particulate Air», is the first characteristic of an air purifier. High Efficiency Particulate Air, which stands for High Efficiency Particulate Retention. A system that uses a filter in this category can make life better, safer, more comfortable.

The principle of operation

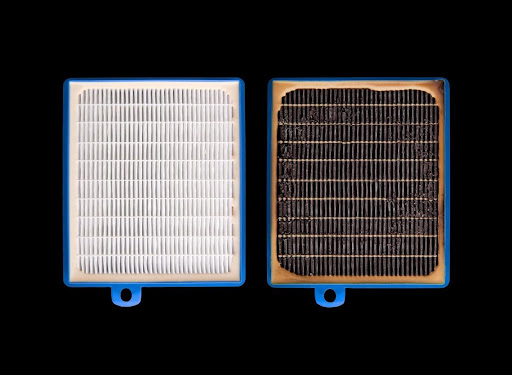

Hepa filters for clean rooms have a very high coefficient of precision, productivity. It is not reasonable to use as a cleaner of large dust particles, fluff, etc. Will not justify the installation financially — will require replacement from clogging soon. It is worth it to install a buffer — a prefilter to appreciate the work of hepa.

How does it work? The cleaning system is three-phase:

- Diffusion. This process removes particles of less than 0.1 μm in size. Small, randomly moving particles are knocked out by a direct air stream, passing between the filter fibers, on which they then settle.

- Inertia (impact). Particles are large, heavy, with a diameter of 0.3 microns, and are unable to bypass the fibers-obstacles. The direction of air movement becomes their trajectory, they move straight ahead and are trapped on the filter.

- Interception. Maximum penetration is the main indicator of medium particles. They are large for diffusion, and do not “reach” the inertia. The entanglement effect affects all particles: in the process of cleaning, they accumulate, one by one cling to the fibers, to each other, etc.

The classification of hepa filters is directly related to the degree to which fine particles are caught. How is it evaluated? The number of dust particles (about 0.3 micron per 1 L of air) that have passed through the filter and returned back into the environment is determined empirically. According to the European standard, the efficiency in percentages by class goes from ≥ 85 to ≥ 99, 999995. The higher the percentage value, the better the air is purified.

Benefits and uses

The classes of hepa filters are an indication of their capabilities. At home, elements of class 10-13 are acceptable: simple air cleaners, vacuum cleaners, ventilation systems. Washable models are relevant for vacuum cleaners, more expensive equipment — higher class of filter.

Good quality air purifiers are equipped with HEPA H11 — a sufficient option for quality filtration of circulating air.

15-17 are used in cosmetology, industry, medicine. For example, hepa aerosol filters are put in the last stage of purification in multi-stage supply ventilation systems. The microfiber structure of the elements prevents radioactive, toxic dust, dangerous viruses, microorganisms. High level filtration hepa filters are used in medical facilities (operating theatres, laboratories, intensive care units), pharmaceutical production facilities, precision instruments, clean areas in microbiology, microelectronics, food industry, etc.

Fine filters are widely used, have a number of advantages.

- Absolute efficiency rate (up to 99.99%).

- Low initial resistance.

- High dust holding capacity.

- Protection against bacteria.

- Safe manufacturing material.

- Easy care and installation.

Types

Filters of this type are disposable and reusable.

The first ones are based on fiberglass or paper. The material is thin, fibrous (fibers with a diameter of 0.65-6.5 microns, 10-40 microns between the threads), folded like an accordion, in several layers. The advantage is that due to the increase in the working plane of the permeable surface the resistance force to the air flow is minimized. The result is an excellent result. The filter material, pleated in a small frame, clogs faster. The disadvantage is the limited operating time.

What is a reusable hepa filter? The manufacturing material is fluoroplastic (W in the name). The element can be washed, put back into operation.

Today manufacturers offer cleaning elements:

- in plastic housings, metal, galvanized and stainless steel, sheet metal, extruded aluminum;

- with seals on the inlet and outlet;

- with safety nets;

- with adhesive, aluminum separation, etc.